Tact switch Click sound and Feel

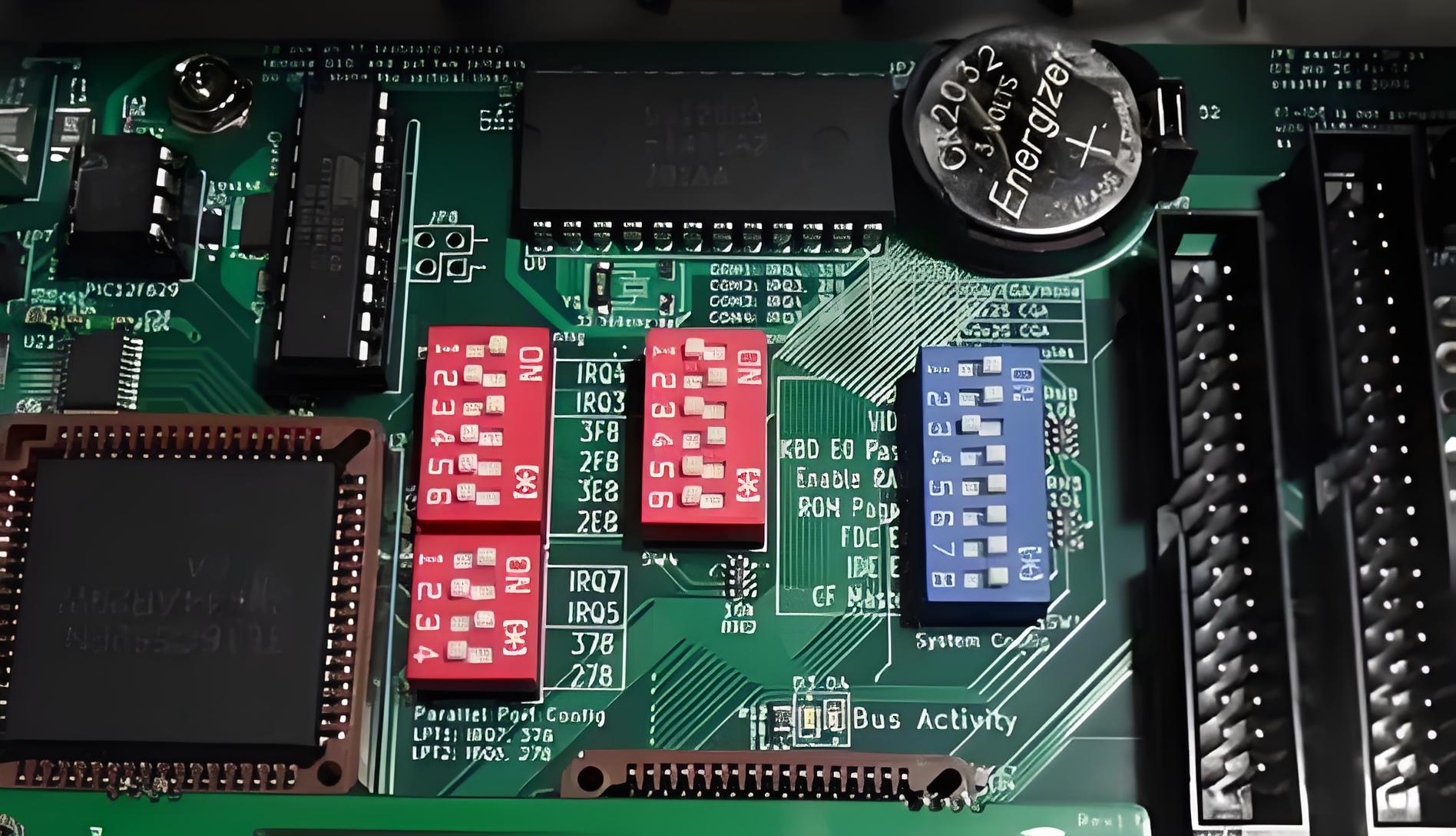

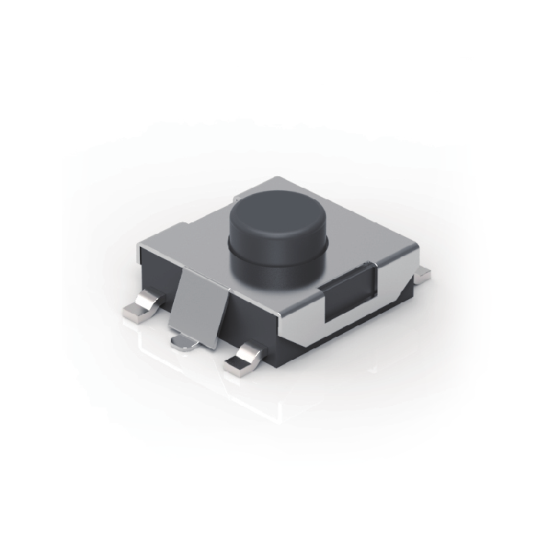

Electromechanical switches, such as tactile and pushbutton types, generate both tactile and audible feedback through their internal mechanical structures. These switches typically produce a distinct physical sensation—often described as a “click” or “bump”—along with an audible sound upon actuation. The overall tactile experience of a switch is determined by its click ratio, travel distance, and the associated sound characteristics.

-1045.png)

Tact Switch Click Sound and Feel

The tactile feedback experienced when pressing the switch is generated by an internal mechanism that often includes a metal dome or similar component. Upon actuation, the dome collapses, completing the electrical circuit while delivering a tactile response. When pressure is released, the dome returns to its original shape, thereby breaking the circuit. The force required to activate the switch, referred to as the operating force, varies among different switch designs. Switches with lower operating forces generally offer quieter and softer tactile responses.

The audible feedback, commonly perceived as a “click,” originates from the same mechanical action responsible for the tactile sensation. As the metal dome or internal mechanism snaps into place, it generates a sound that signals the activation of the switch.

_09.jpg)

-1117.png)

Selecting Switch Click Sound

When selecting a switch for a specific application, the click sound should be taken into account. Variations in sound can be controlled by choosing switches with different travel distances and actuation forces. Several factors influence the quietness or softness of the tactile feedback provided by electromechanical switches.

The material composition and design of the metal dome or internal components play a significant role in determining the acoustic and tactile properties. Using softer materials or implementing designs that reduce the required actuation force can effectively minimize noise and provide a more subdued tactile response.

Switches with lower click ratios or reduced actuation forces tend to produce less audible feedback. Quiet and soft tactile switches are especially important in noise-sensitive environments such as medical equipment, automotive interiors, and consumer electronics.

The amount of force needed to actuate the switch, known as the operating force, varies across switch types. Higher operating forces typically result in louder and firmer tactile responses. Additionally, the travel distance—the extent to which the switch moves when pressed—also influences the feedback. Shorter travel distances often lead to a gentler and quieter response.

Furthermore, certain switches incorporate damping materials designed to absorb sound and suppress noise during operation. Lubrication applied to internal components can also help reduce friction and noise, contributing to a smoother and quieter performance.